High virtue plastic valves and PTFE Solenoid esteems are produced using PTFE, PVDF and other high immaculateness plastics. These sorts of valves are delivered by the claim to fame plastic fabricator producers for use in extreme and basic assistance applications for the Pharmaceutical, Defense, Alternate Energy, Semiconductor, Medical and Chemical ventures to control liquid stream distantly. Since these items, also What is Solenoid Valve? are regularly used in a destructive research facility climate or cleanroom mechanization climate, the high virtue plastics of development guarantee the best outcomes against consumption, and their substance resistances offer long life inside the application. Custom liquid control items produced using polytetrafluoroethylene (PTFE) and other mechanical plastics can be found in a wide assortment of details to meet the many potential applications. They can frequently be customized to a client’s specific prerequisites.

Solenoid Values

PTFE Solenoid Valves are utilized to control the liquid stream distantly. Their utilization is becoming progressively famous in a wide assortment of modern applications because of their general simplistic nature and moderate establishment cost. With a gigantic scope of high immaculateness plastic valves available, production lines and plants all through the modern area are effectively ready to track down the right valve that meets the specific particulars of their planned use.

How They Work

Solenoid valves are electrically activated to either their open or shut position. The valve parts work by permitting or limiting fluid stream contingent upon whether they depend on an electrical flow. The trigger gadget is typically an electromagnet loop that initiates when taken care of an electric flow, drawing in an unclogger or other valve stem part to changing the condition of the mechanical gadget. This thus permits or forestalls fluid stream. When the electromagnet is deactivated, the unclogger is returned to its unique position regularly through a bring spring back.

Valve Types

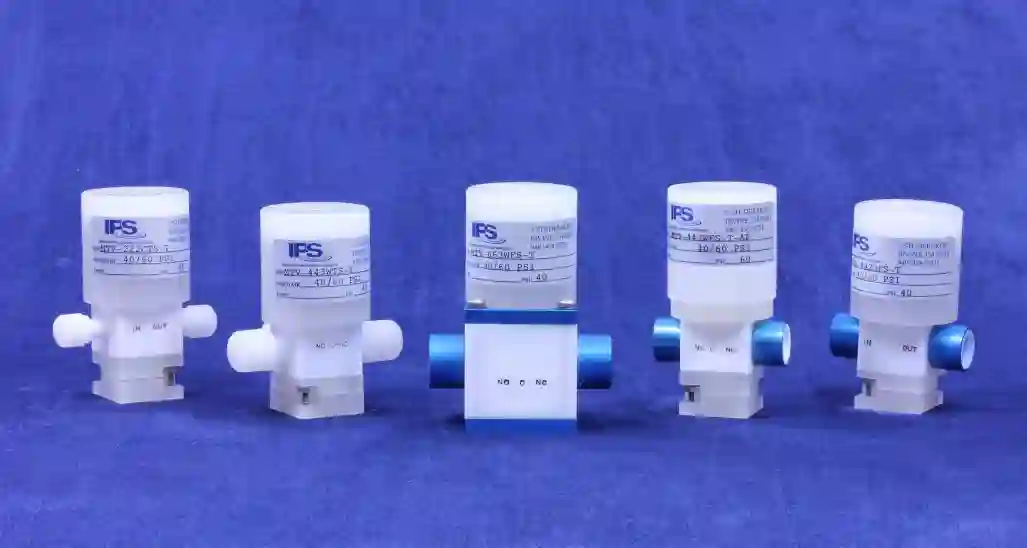

Their strategy for activity sorts valves. Valve activation strategies incorporate; solenoid impelled, pneumatic incited, manual incited, with normal choices for inside or remotely, steered and direct-acting valves. They can also be ordered by the number of stream ways (or ports) planned into the valve. Another standard technique for the order is the stream arrangement of Normally Open (“NO”) and Normally Closed (“NC”). Subsequently, one could demand a Three-Way Normally Open Solenoid Valve.

Piece

Every valve is uncommonly built considering its common reason. The mind-boggling assortment of capacities that solenoid valves can serve implies they can be produced using a different choice of materials. Key contemplations while picking the Body, Solenoid and Seal materials are the general significance of components like unwavering quality, strength, cost and reason explicit characteristics like liquid similarity.

PTFE (polytetrafluoroethylene) is a modern plastic valuable for its compound dormancy and its high-virtue properties, permitting it to perform well considerably under excessive temperatures, dangerous conditions and inside acidic liquids. Furthermore, the synthetic resistance properties make PTFE a strikingly flexible polymer, and consequently, PTFE solenoid valves are generally utilized in brutal modern applications.

PVDF plastic (polyvinylidene fluoride) is a modern polymer with great high virtue, scraped spot resistant, and substance resistant properties. It is additionally accessible in FDA agreeable grades. PVDF is an innovative plastic material from the fluoropolymer family and is commonly utilized in applications and cycles whose outrageous conditions require the most important virtue. For example, PVDF high immaculateness plastic valves are especially fit to unfavorable conditions because of the material’s solidarity, resistance to acids, bases, solvents and warmth, just as its property of low smoke age in case of a fire.

The fixing surfaces of common High Purity Plastic and PTFE Solenoid Valves can be bought in three distinctive inside setups; PTFE with Viton O-Rings, PTFE with Kalrez O-Rings, and an all PTFE wetted surface plan. The valves are shielded from the unforgiving modern climate when inactivity by enduring, solid PTFE stomachs, guaranteeing a long and dependable help life. Every one of these PTFE Solenoid Valve types can be arranged to fit different shapes, fittings, associations, power supplies and stream designs or uniquely crafted to arrange from forte plastic creation producers.